Context

In the highly competitive automotive industry, quality control is essential to ensure the reliability of vehicles and user safety. A failure in quality control can severely jeopardize safety, result in significant financial costs, and cause substantial reputational damage to the company involved.

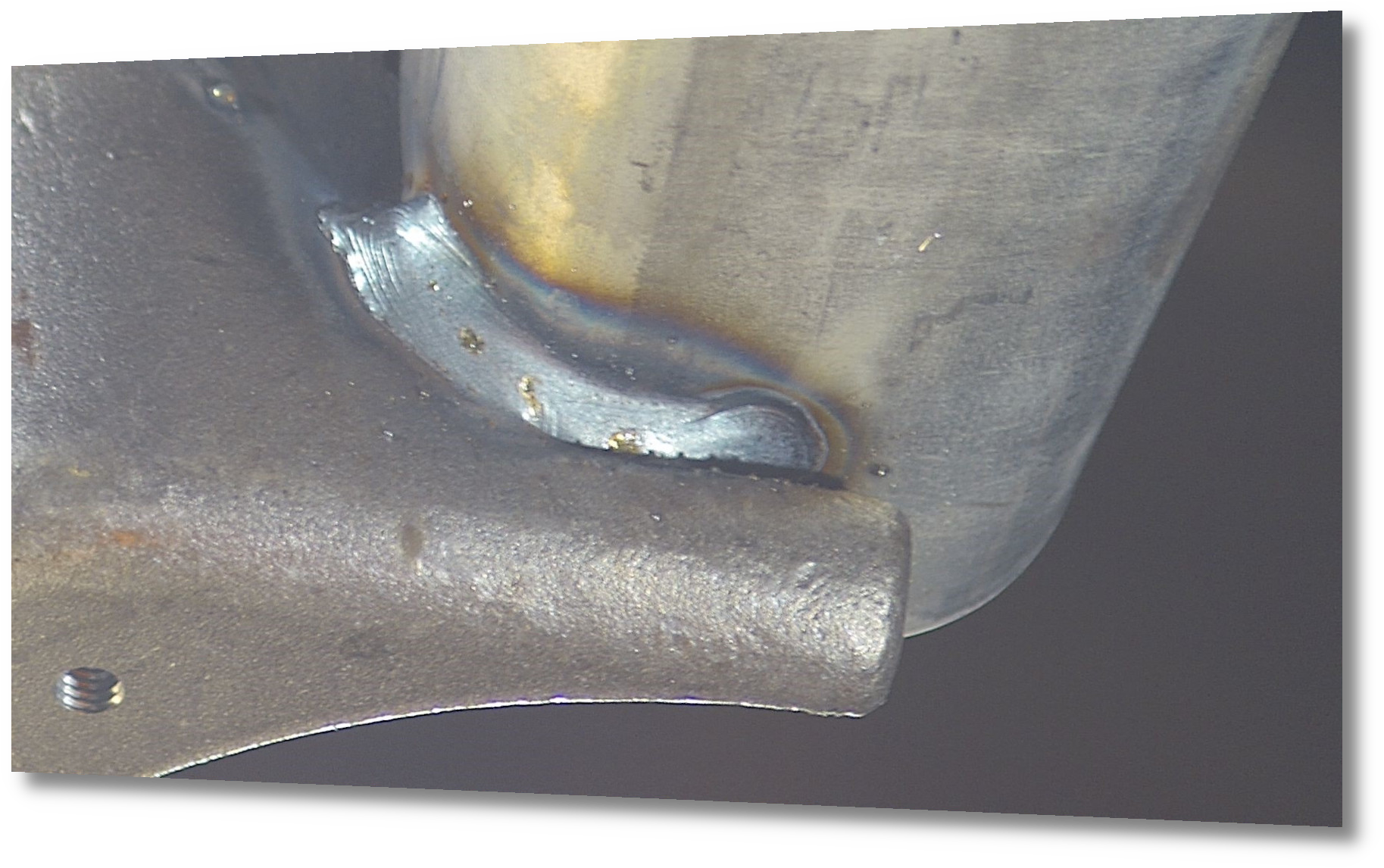

One of the challenges for Renault is to improve the reliability of quality control for welding seams in automotive body manufacturing. Currently, this inspection is consistently performed by a human operator due to the legal dimension related to user safety. During an industrial process, this task is resource-consuming. The key challenge is to develop an AI-based solution that reduces the number of inspections required by the operator through automated pre-validation.

Within the Confiance.ai Research Program, Renault Group and SystemX worked jointly on the development of trustworthy AI components tackling this problem. Now part of the European Trustworthy Foundation (ETF), we want to ensure that these tools effectively validate the proposed AI-Component according to the trustworthy criteria defined by the industry (Intended Purpose).